biomedical textiles.

At Our Core –

Agility

Credibility

Curiosity

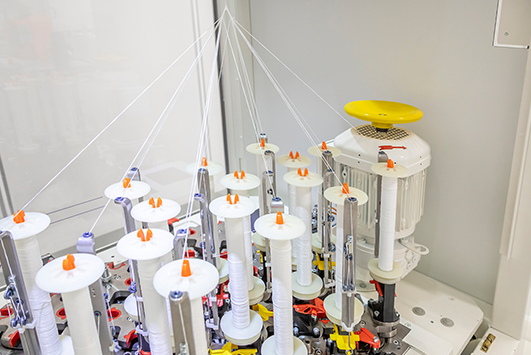

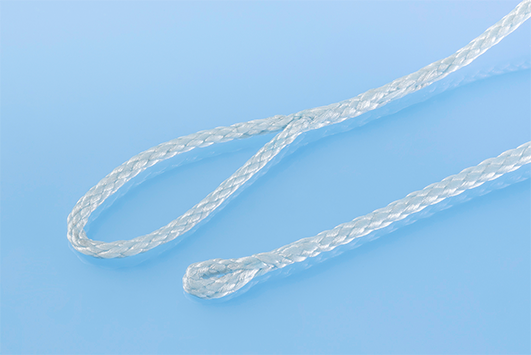

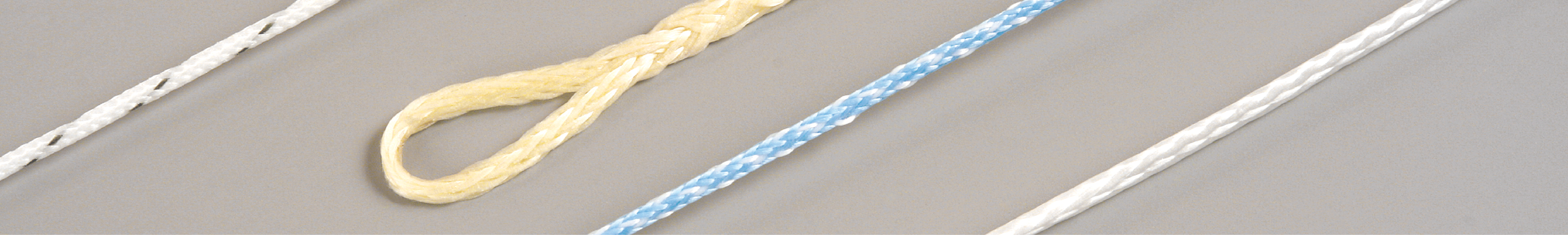

High Density Braiding

in Booth 2127

Endovascular E-Book

and benefits of our biomedical textiles in cardiovascular and endovascular procedures and showcase how our expertise enables the development and manufacturing of the world’s most trusted next-generation medical devices.

Your partner in custom biomedical textiles

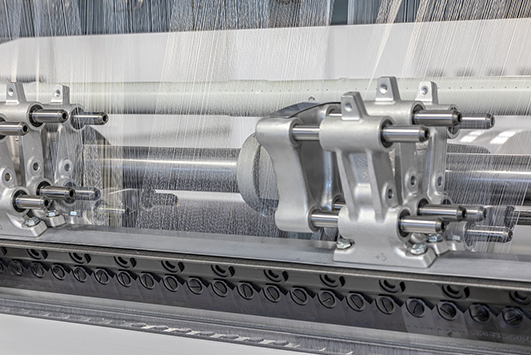

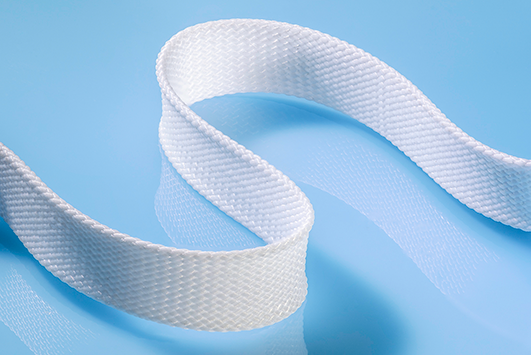

If you can think it, we can build it. At Cortland Biomedical, all of the biomedical textile products we create are custom-manufactured to your design inputs and fabricated for a specific medical device application. Our unique combination of advanced equipment, a seasoned medical textile engineering team, and first-rate R&D capabilities allows us to tackle your complex challenges with the innovation and agility you expect and deserve.

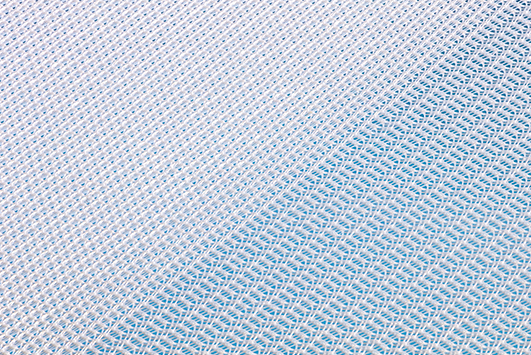

Purpose-Built Biomedical Textile Structures

This includes working with a wide range of high-performance synthetic biomaterials for applications in the medical device industry. Never comfortable with the status quo, we tackle complex biomedical textile challenges with innovation and agility.

If you can think it, we can build it. At Cortland Biomedical, all of the biomedical textile products we create are custom-manufactured to your design inputs and fabricated for a specific medical device application. Our unique combination of advanced equipment, a seasoned medical textile engineering team, and first-rate R&D capabilities allows us to tackle your complex challenges with the innovation and agility you expect and deserve.

Act with speed and flexibility.

Be a trustworthy and competent partner.

Commit to discovery and exploration.

We offer you:

- A proven track record of working with research and development teams in the medical market to provide innovative solutions

- A product development team versed in modern textile forming techniques

- A cross-functional team of engineers available to work on all aspects of the design, process development, quality assurance and validation of a product

- Agile manufacturing

We offer you:

- A proven track record of working with research and development teams in the medical market to provide innovative solutions

- A product development team versed in modern textile forming techniques

- A cross-functional team of engineers available to work on all aspects of the design, process development, quality assurance and validation of a product

- Agile manufacturing

Our Disciplined Approach

We rapidly deploy innovative ideas into fully developed commercial medical products.

![]()

PHASE 1

Concept and Feasibility

![]()

PHASE 2

Design and Development

![]()

PHASE 3

Scale-Up and Design Transfer

![]()

PHASE 4

Commercial Launch

![]()

PHASE 1

Concept and Feasibility

![]()

PHASE 2

Design and Development

![]()

PHASE 3

Scale-Up and Design Transfer

![]()

PHASE 4

Commercial Launch