Today’s biomedical textile structures can be engineered to be innovative enough to support and promote the healing and even the regeneration of damaged cardiovascular tissue, with complex and fully customizable geometries.

![]()

Biomedical Textiles for Cardiovascular and Endovascular Applications

Today’s biomedical textile structures can be engineered to be innovative enough to support and promote the healing and even the regeneration of damaged cardiovascular tissue, with complex and fully customizable geometries.

![]()

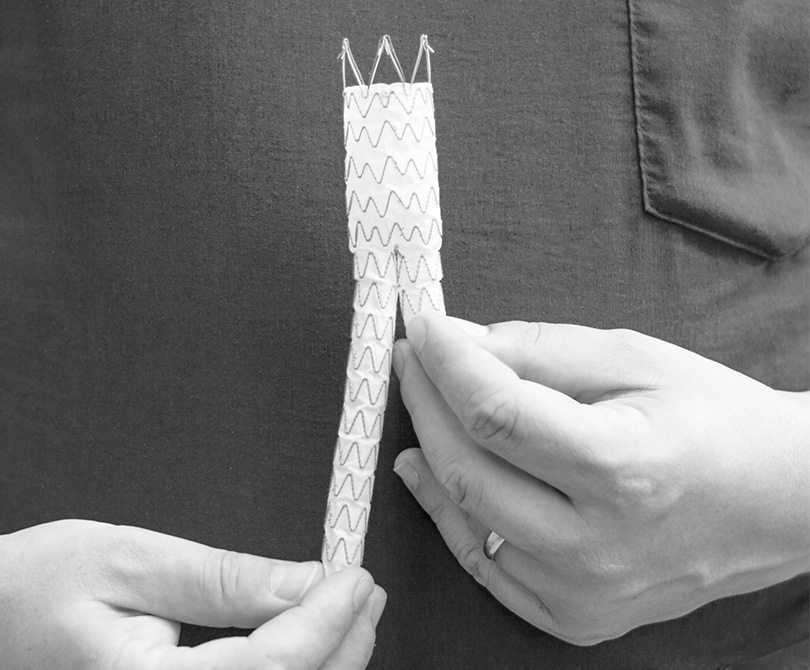

Implantable textiles can be formed via knitting, braiding or weaving of medical-grade fibers. Based on the processing parameters and biomaterials selected (such as, ultra-high molecular weight polyethylene, polyester, polypropylene etc.), the characteristics of the fabric can be tailored by design engineers to the specific needs of the surgical application. For example, a tapered woven that changes the direction of a few fibers can allow tape itself to be more easily threaded through holes in the body by a surgeon. Textiles can also be used for composite products combining polymeric and metallic filaments, for example a stent graft composite (mixing wire with polyester).

The medical device market continues to move towards smaller, lower profile options to facilitate less invasive procedures. Today’s textiles have the flexibility and shape transformation capabilities to be engineered for insertion through a smaller catheter and to expand within the vessels, allowing for minimally invasive delivery methods without sacrificing any mechanical integrity. This is particularly beneficial for patients with small vessels, and for repairs in the three branches of the aortic arch, which has long been challenging. Even in thoracic surgery, where pressures are significantly higher than in abdominal areas, textiles have proven very successful due to the development of high-performance medical grade yarns and dense fabric constructions. Spacer fabrics — porous structures combining textile sheets and distance fibers to offer high absorption capacities – are well-suited for cardiovascular applications such as in heart valves as buttresses.

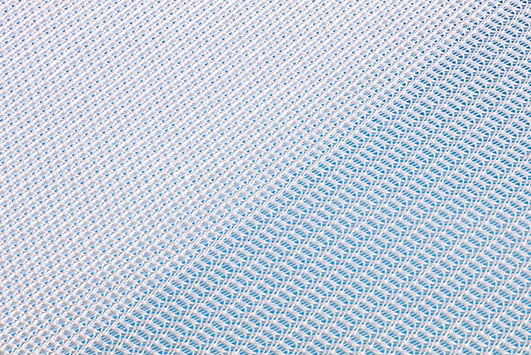

Warp knitting is especially ideal for creating textile products for vascular applications (especially for mitral heart valve replacement) because it can produce very thin, dense textile structures that prevent blood leakage around the valve. Porosity can be tailored to recruit the desired cell by size, creating specialized regions of tissue regeneration. Densities can be rapidly changed so you can transition from dense to porous within a single fabric. For cardiovascular fabrics, this means blood leakage can be prevented inside the valve while native tissue ingrowth is encouraged outside. Knits are very compliant allowing the implant to stretch and move with the body, reducing patient discomfort and restoring natural mobility.

Biomedical textiles can be used in lower profile devices and less invasive cardiovascular and endovascular procedures/applications including:

- Heart valve replacement

- Aortic arch reinforcement

- Stent graft covering

- Carotid artery repair fabric

- Tissue grafts

- PAD (peripheral artery disease) treatment

- Hypertension treatment

- Angioplasty balloon/reinforcement

- Distal/embolic protection

- Coronary bypass grafts

- Cardiovascular patches

- Vascular prostheses

- Branch vessel filtration

- Sewing rings for heart valves

Key benefits of textiles

- Less invasive

- Lower profile

- Controlled density and porosity

- Flexibility

- Shape transformation

- High tensile strength

- Biocompatibility

- Inherent capabilities for promoting healing of cardiovascular tissue

- Radial reinforcement and expansion

Cortland Biomedical is trusted by leading medical device OEMs to enable more innovative, lower profile devices by designing and engineering braided, woven and knitted biomedical textiles fit-for-purpose. We have the expertise, capabilities and machinery to create textile designs unrivaled in their complexity, resulting in cardiovascular products that can be simultaneously low profile and mechanically robust.

Take a closer look at our advanced capabilities for creating cardiovascular structures:

Woven Fabrics – Weaving technology can create heart valve fabrics and other cardiovascular products by interlacing combinations of two or more monofilament or multifilament non-absorbable yarns in a perpendicular fashion. Woven fabric configurations can include tubular, flat, bifurcated, tapered, or near-net fabrics that are beneficial due to their low porosity (which is important for containment and cardiovascular fluid transfer), dimensional stability and high-tensile strength. Using state-of-the-art weaving machines, we can expertly perform narrow weaving, tubular weaving, leno weaving and bifurcated weaving to create textile structures for use in the cardiovascular system, such as heart valves and carotid patches.

Knitted Fabrics – Knitted mesh structures and fabrics can be created by interlocking loops of yarn or metal in a weft or warp pattern to form flat, broad, or tubular configurations with open spaces to promote native tissue growth as needed. Applications of knitted heart valve fabrics include vascular prosthesis, hemostasis, cardiac support devices, and valve sewing cuffs. Warp knitting can produce very thin, dense textile structures that prevent blood leakage around the valve.

Read more.

Implantable textiles can be formed via knitting, braiding or weaving of medical-grade fibers. Based on the processing parameters and biomaterials selected (such as, ultra-high molecular weight polyethylene, polyester, polypropylene etc.), the characteristics of the fabric can be tailored by design engineers to the specific needs of the surgical application. For example, a tapered woven that changes the direction of a few fibers can allow tape itself to be more easily threaded through holes in the body by a surgeon. Textiles can also be used for composite products combining polymeric and metallic filaments, for example a stent graft composite (mixing wire with polyester).

The medical device market continues to move towards smaller, lower profile options to facilitate less invasive procedures. Today’s textiles have the flexibility and shape transformation capabilities to be engineered for insertion through a smaller catheter and to expand within the vessels, allowing for minimally invasive delivery methods without sacrificing any mechanical integrity. This is particularly beneficial for patients with small vessels, and for repairs in the three branches of the aortic arch, which has long been challenging. Even in thoracic surgery, where pressures are significantly higher than in abdominal areas, textiles have proven very successful due to the development of high-performance medical grade yarns and dense fabric constructions.

Warp knitting is especially ideal for creating textile products for vascular applications (especially for mitral heart valve replacement) because it can produce very thin, dense textile structures that prevent blood leakage around the valve. Porosity can be tailored to recruit the desired cell by size, creating specialized regions of tissue regeneration. Densities can be rapidly changed so you can transition from dense to porous within a single fabric. For cardiovascular fabrics, this means blood leakage can be prevented inside the valve while native tissue ingrowth is encouraged outside. Knits are very compliant allowing the implant to stretch and move with the body, reducing patient discomfort and restoring natural mobility.

Biomedical textiles can be used in lower profile devices and less invasive cardiovascular and endovascular procedures/applications including:

- Heart valve replacement

- Aortic arch reinforcement

- Stent graft covering

- Carotid artery repair fabric

- Tissue grafts

- PAD (peripheral artery disease) treatment

- Hypertension treatment

- Angioplasty balloon/reinforcement

- Distal/embolic protection

- Coronary bypass grafts

- Cardiovascular patches

- Vascular prostheses

- Branch vessel filtration

- Sewing rings for heart valves

Key benefits of textiles

- Less invasive

- Lower profile

- Controlled density and porosity

- Flexibility

- Shape transformation

- High tensile strength

- Biocompatibility

- Inherent capabilities for promoting healing of cardiovascular tissue

- Radial reinforcement and expansion

Cortland Biomedical is trusted by leading medical device OEMs to enable more innovative, lower profile devices by designing and engineering braided, woven and knitted biomedical textiles fit-for-purpose. We have the expertise, capabilities and machinery to create textile designs unrivaled in their complexity, resulting in cardiovascular products that can be simultaneously low profile and mechanically robust.

Read more.