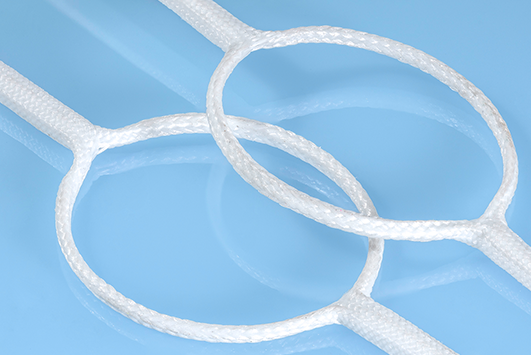

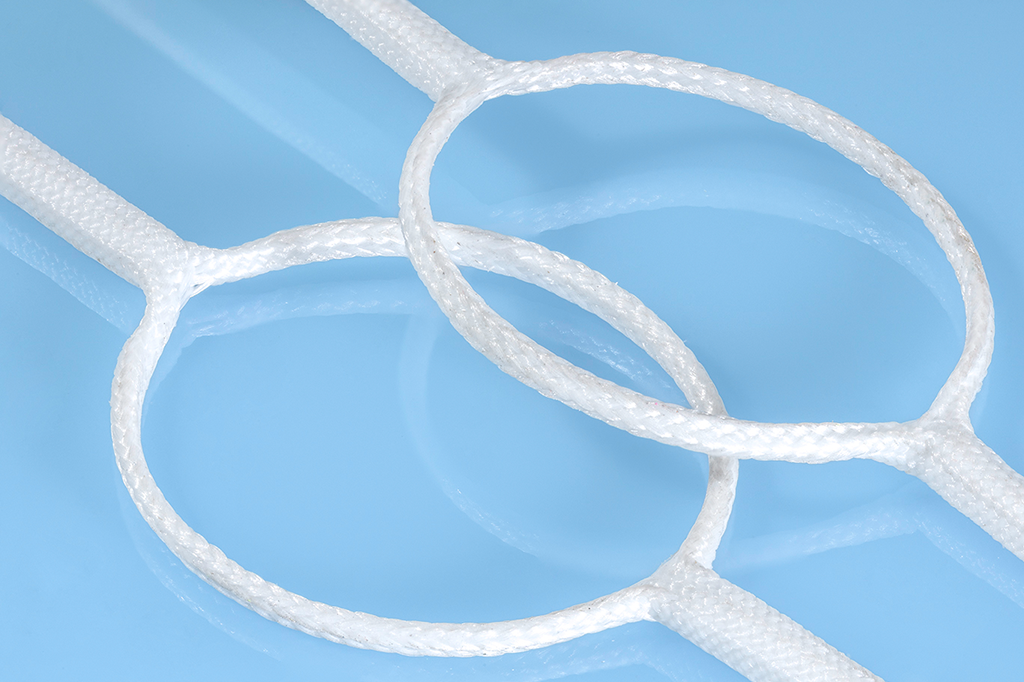

Braided loops provide ideal anchoring options for orthopedic applications. Their size, flexibility and strength allow them to be used in various arthroscopic procedures.

![]()

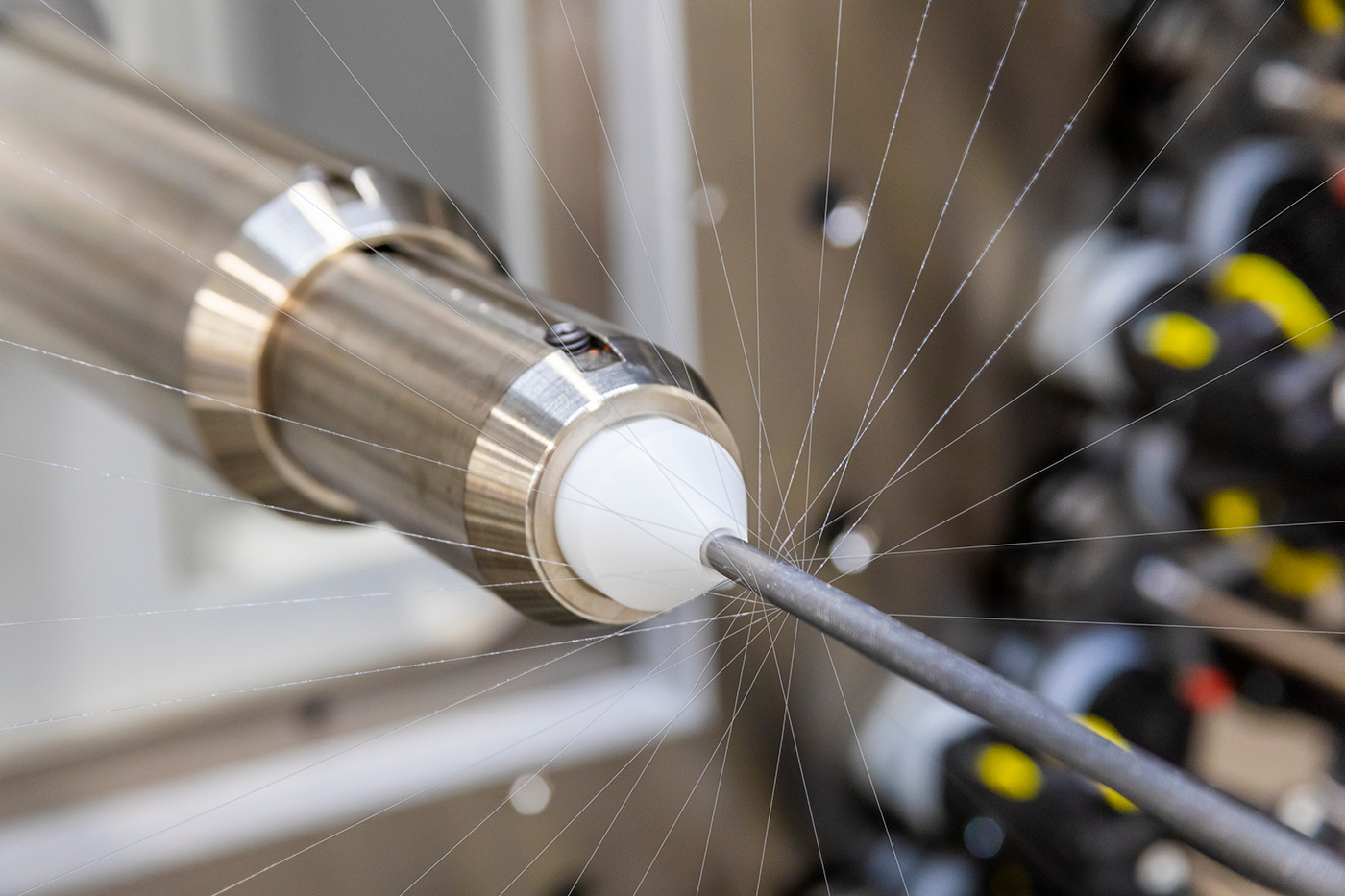

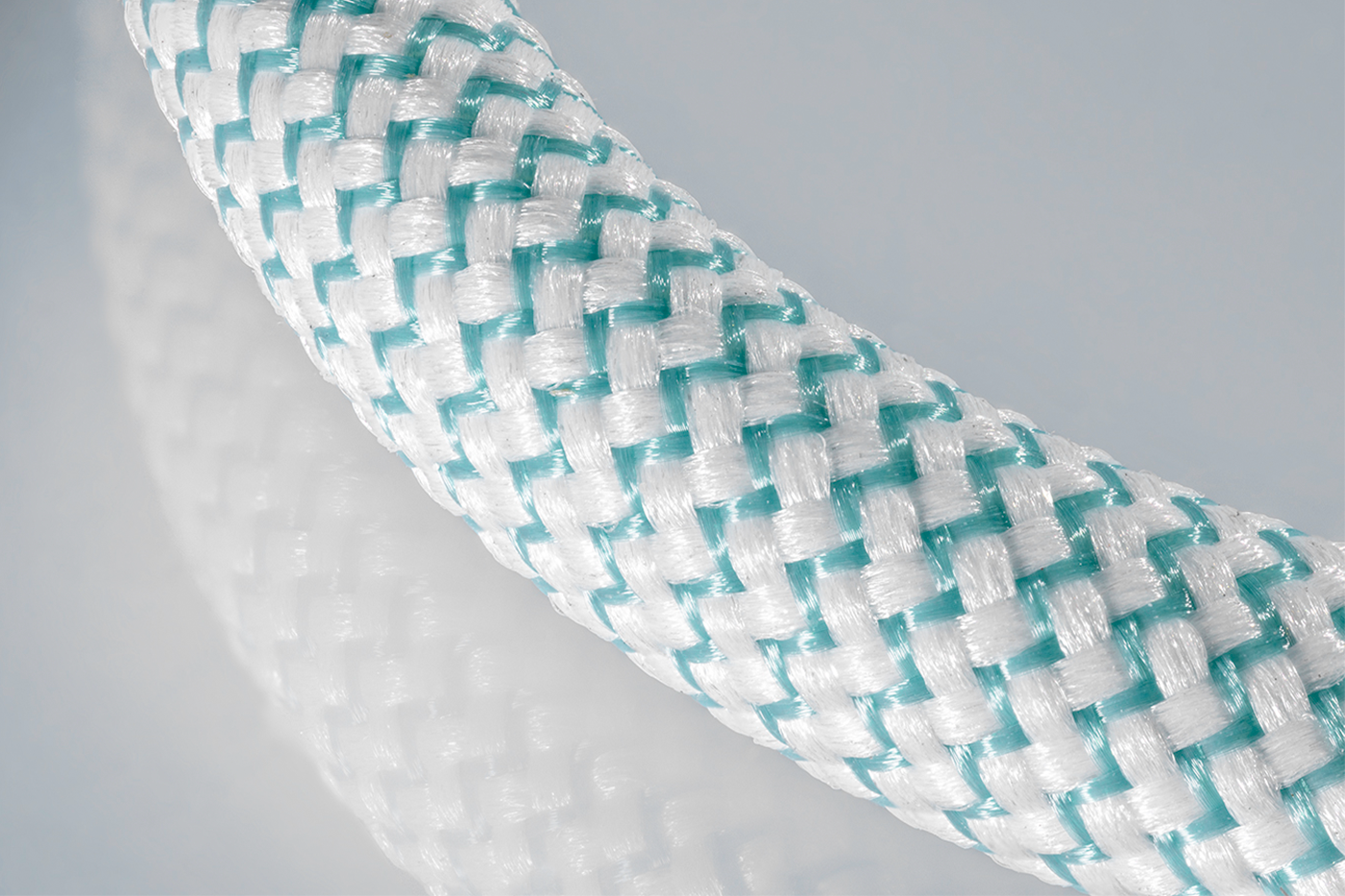

Braiding

Braided loops provide ideal anchoring options for orthopedic applications. Their size, flexibility and strength allow them to be used in various arthroscopic procedures.

![]()

Braiding Capabilities

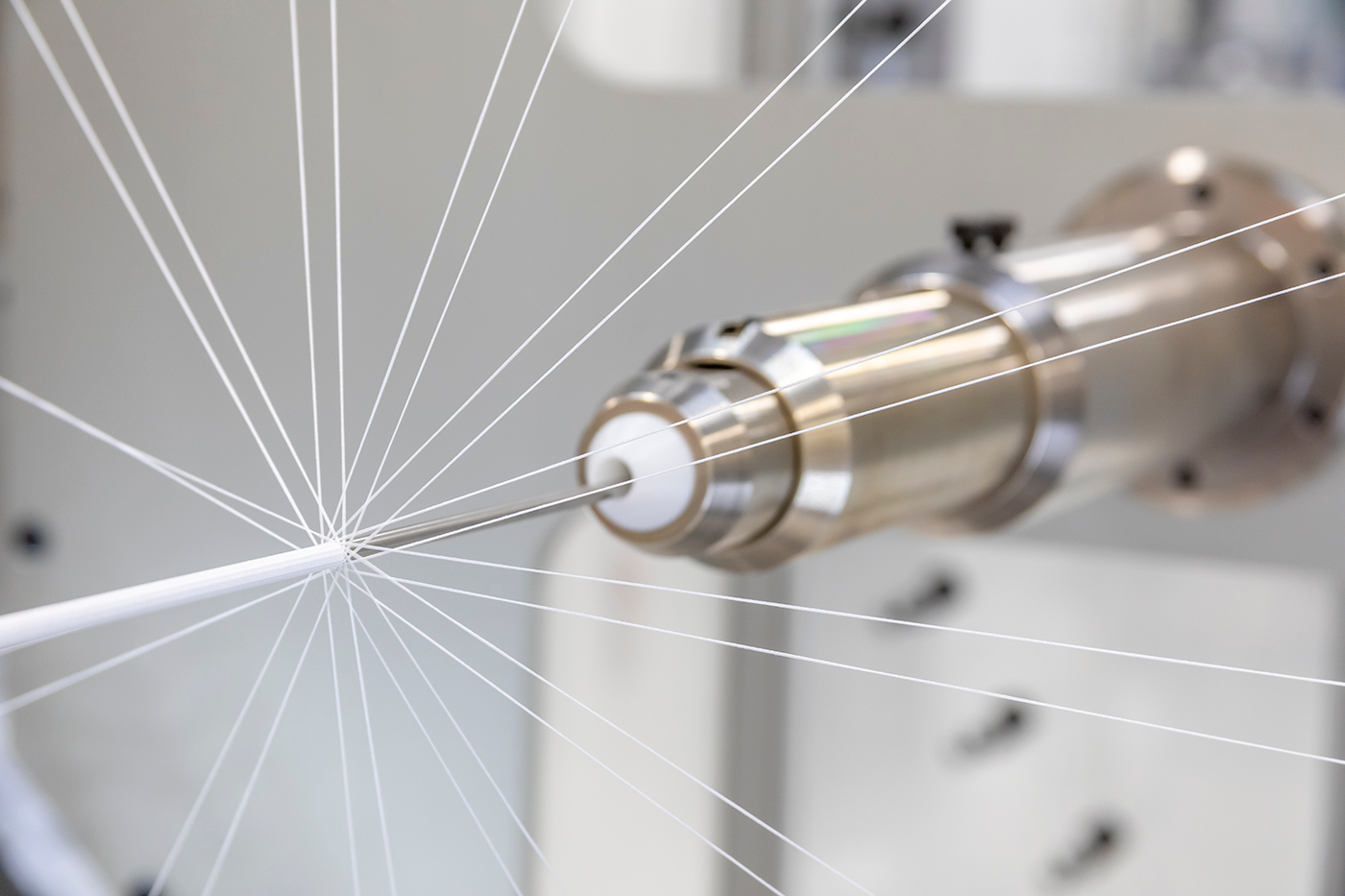

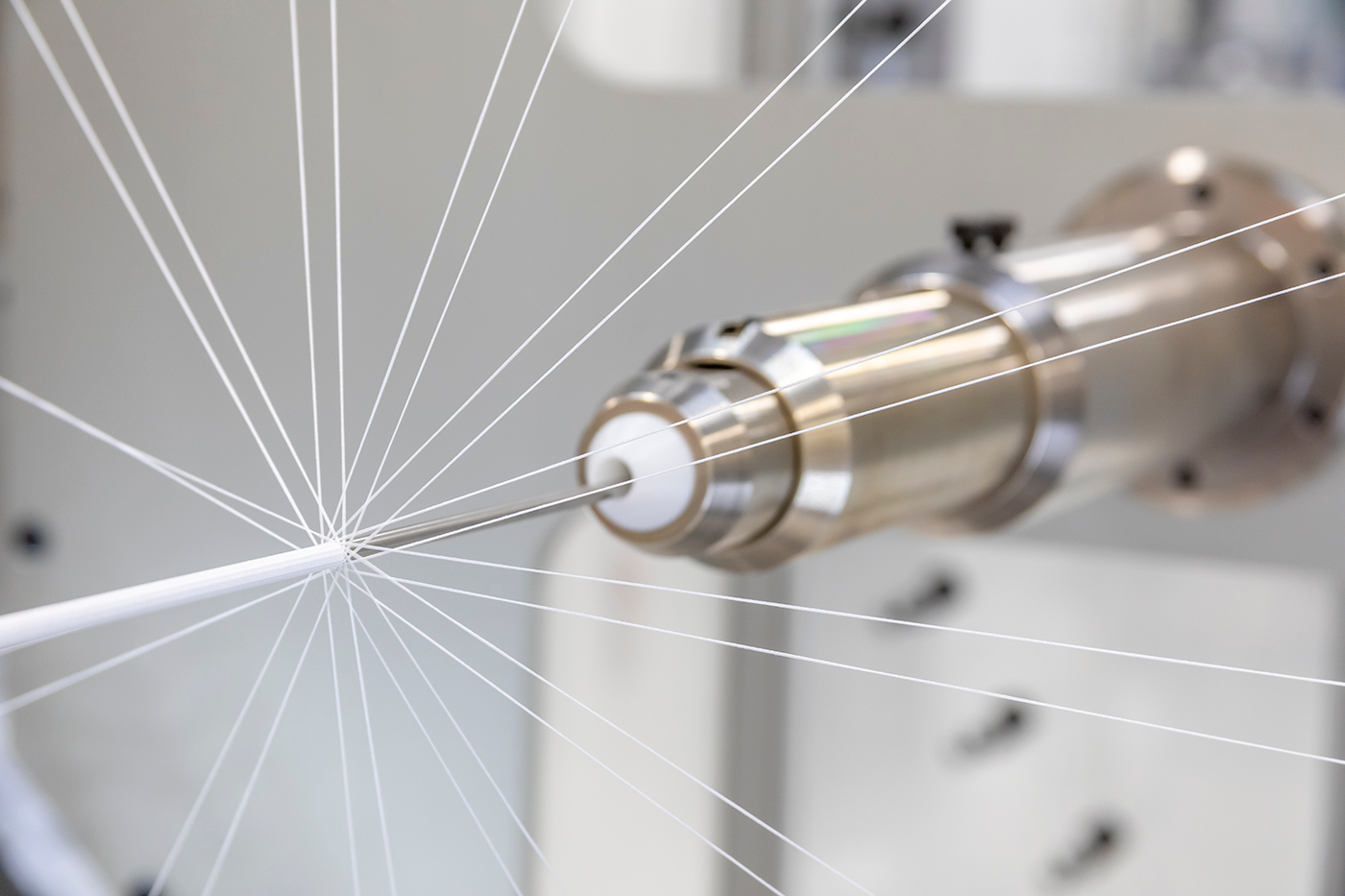

We have gone to considerable effort to install the latest in braiding technology to accommodate the design needs of the next generation of medical device products. From modern machinery equipped with the latest in tension control, to fully PLC driven braiding software allowing for dynamic braid design, to contact surface engineered to safely handle the most delicate of biomaterials, we are leading the charge to bring braiding to the 21st century.

Biomedical Textile Braiding Capabilities

Braiding textiles is part of our heritage and something that we have done well since our inception.Our team has focused on elevating the technology to the next level.

We have gone to considerable effort to install the latest in braiding technology to accommodate the design needs of the next generation of medical device products. From modern machinery equipped with the latest in tension control, to fully PLC driven braiding software allowing for dynamic braid design to contact surface engineered to safely handle the most delivate of biomaterials, we are leading the charge to bring braidng to the 21st century.

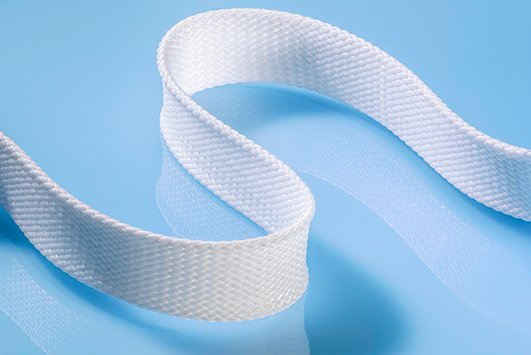

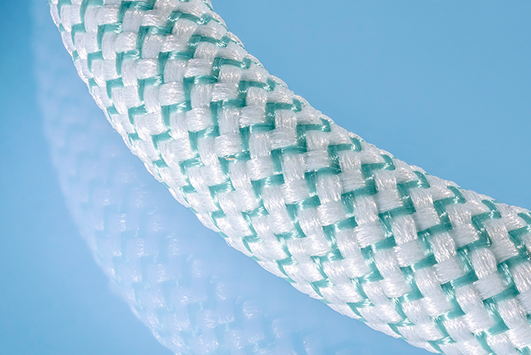

Sample Braiding Products

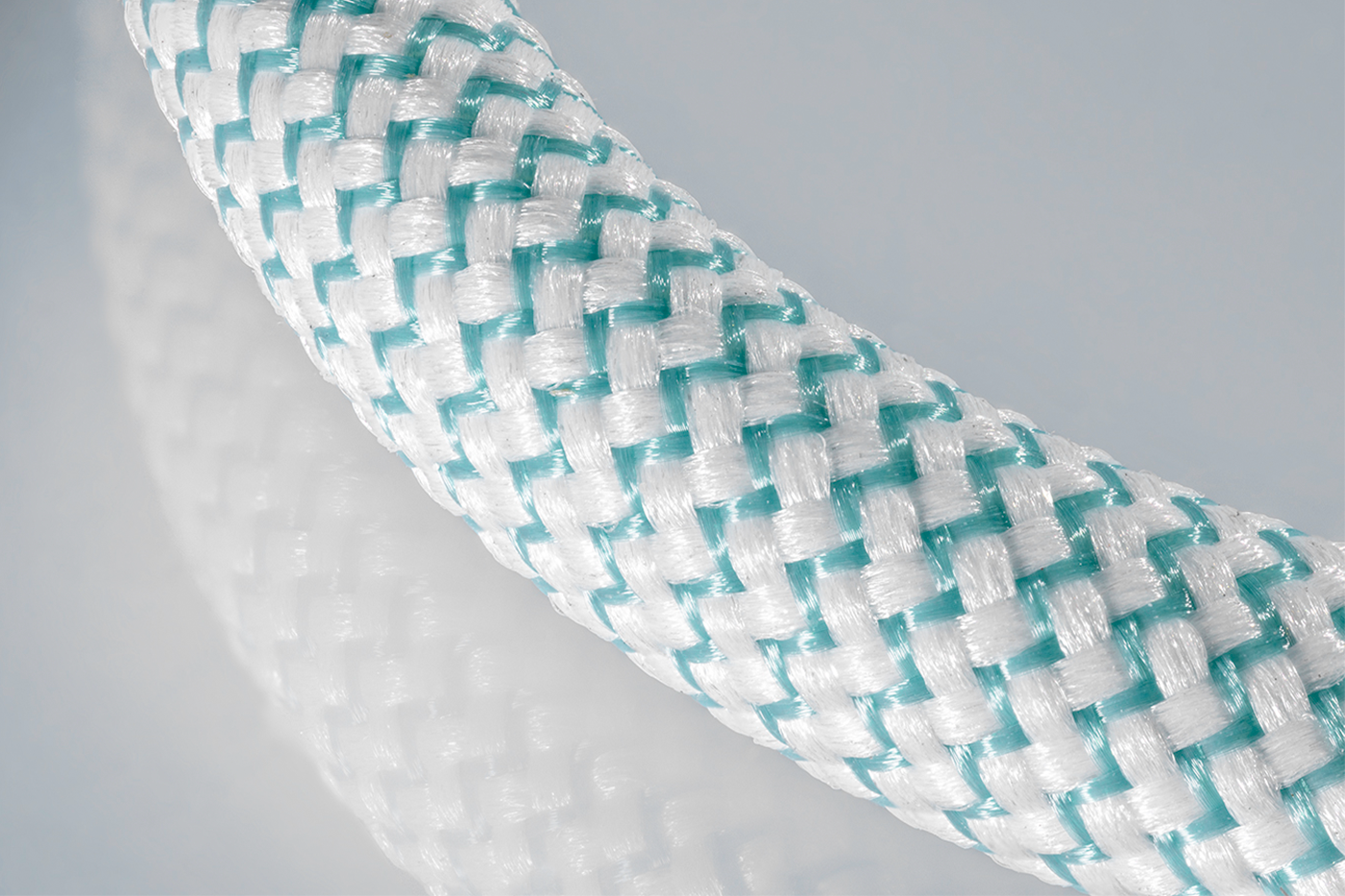

Our lightweight, high performance medical braids offer the strength of steel, with more flexibility.

Types of Braiding Technology

To view our types of braiding technology, select and toggle between options from the menu below.

LOW DENSITY BRAIDING

Low Density Braiding

- Carrier counts ranging from 4 to 16

- Fully electronic braiding equipment allowing variable density structures

- Segment control permitting the design of products with functional regions

- Tension controls capable of handling the finest performance fibers to large diameter surgical grade wires

3D AND BRANCH BRAIDING

3-Dimensional and Branch Braiding

- Carrier counts ranging from 4 to 32

- Ability to create true round tubular braided structures with multiple “furcations”. Examples include:

- 24 end “Bifurcation”– 2, 12 end braids

- 24 end “Trifurcation” — 3, 8 end braids

- 32 end “Octofurcation” — 8, 4 end braids

- Ability to integrate braided eyelets into the product without the need for post-process assembly

- Variable pick density and braid design through an integrated HMI interface

- Hollow lumen braid geometry allows for termination and splicing, creating highly novel device assemblies

HIGH DENSITY BRAIDING

High Density Braiding

- Carrier counts ranging from 32 to 144

- Fully electronic, variable density; differentiate up to 25 segments

- Fine wire/yarn capability with quad roller draw tension control

- Braid over straight and tapered mandrels to allow for complex geometries in high density braided structures

- Ability to process either discrete or continuous products

- Warp axial capability on all machines