13 Jul Developing Heart Valve Fabric with Knitting and Weaving Technologies

Heart valve surgery is a procedure to treat heart valve disease and can involve at least one of the four heart valves not working properly. The four valves are the mitral, the tricuspid, the aortic and the pulmonary – and they work together to keep the blood flowing in the correct direction through the heart. Human tissue is very fragile when folded for small-diameter catheter insertion, but textiles have proven to be a viable alternative for minimally invasive procedures — providing greater strength and more dynamic performance capabilities. Today’s cardiovascular surgeries leverage exciting new medical devices including heart valve fabric solutions that are developed using biomedical textiles and take advantage of their limitless shape and performance possibilities.

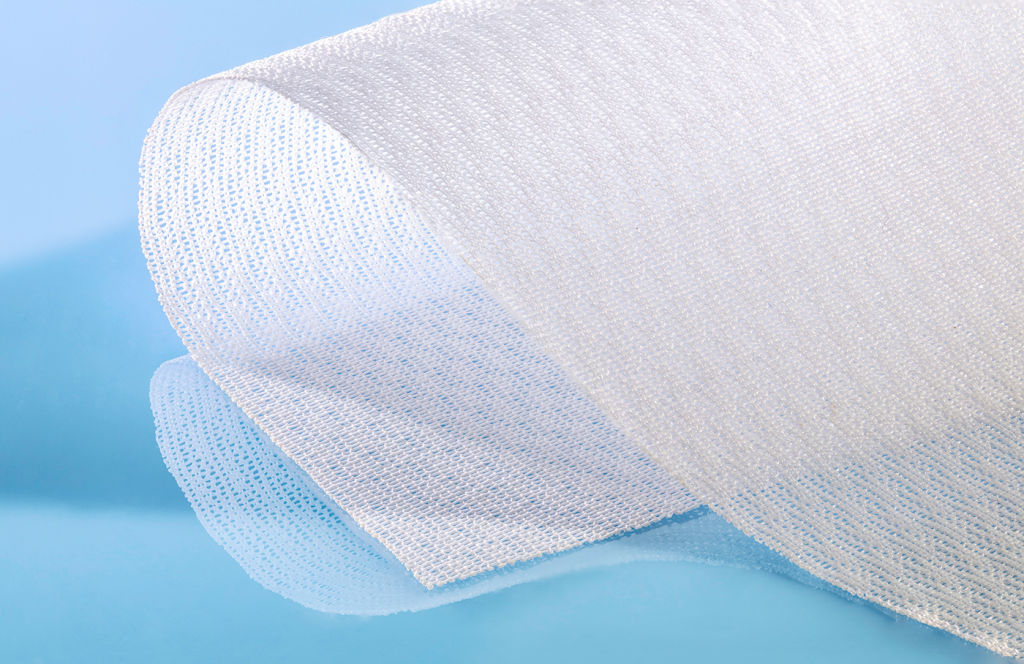

Example of woven heart valve fabric before shaping for medical device use. There are virtually limitless shape and format possibilities.

Biomedical textiles have been incorporated in medical devices for cardiovascular applications for more than 50 years. Initially, textiles were limited primarily to vascular grafts and heart valve sewing cuffs for use in traditional aortic valve repair. As textile structures have become more innovative, with complex and fully customizable geometries, implantable fabrics are no longer limited to traditional applications and can support and promote healing and regeneration of damaged cardiovascular tissue. Today, textiles are used to create biocompatible heart valve fabric, aortic arch reinforcement, stent graft covering, carotid artery repair fabric, tissue grafts, and more.

Not only are textile structures for heart valve fabrics highly customizable in shape and form, but also can be created using various biomaterials to enhance their performance. For example, ultra-high molecular weight polyethylene, polyester, polypropylene etc. The characteristics of the fabric can be tailored by design engineers to the specific needs of the surgical application. Textiles can also be used for composite products combining polymeric and metallic filaments.

Cardiovascular applications require devices that are well-suited for complex anatomies and compatible with soft tissue, which makes biomedical fabric technologies a good fit. Methods for creating heart valve fabric structures commonly include knitting and weaving.

Knitted Heart Valve Fabric

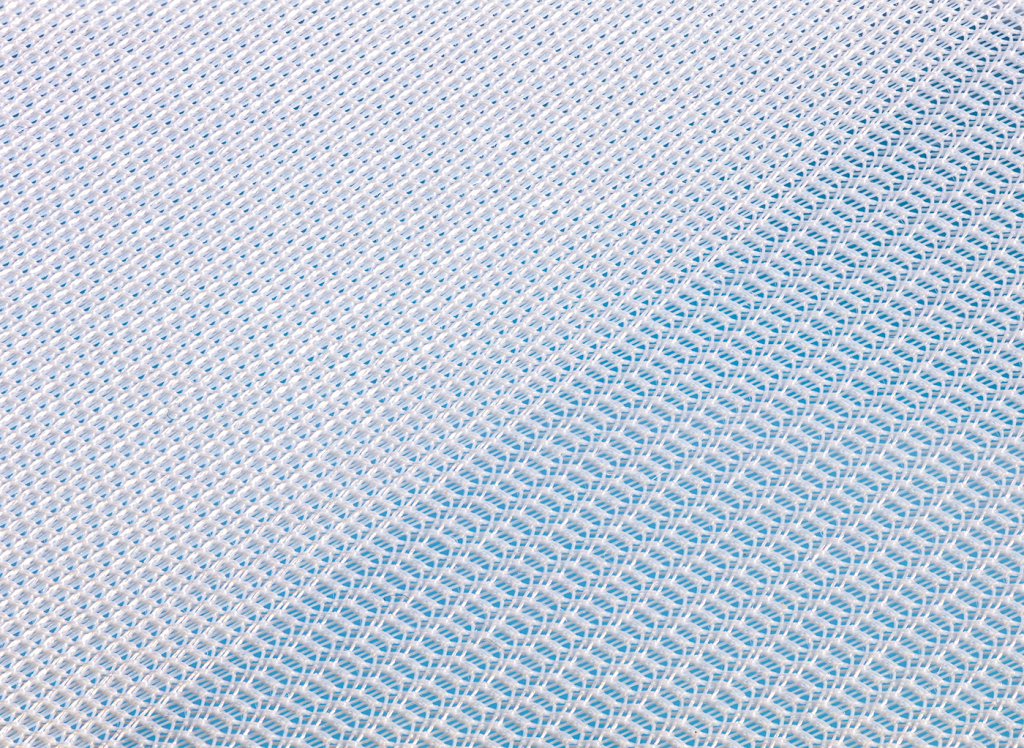

Knitted heart valve fabric structures are formed by interlocking loops of yarn or metal in a weft or warp pattern to form flat, broad, or tubular structures with open spaces to promote native tissue growth as needed. Warp knitting, in particular, is ideal for creating textile products for vascular applications (especially for mitral heart valve replacement) because it can produce very thin, dense textile structures that prevent blood leakage around the valve. Porosity can be tailored to recruit the desired cell by size, creating specialized regions of tissue regeneration. Densities can be rapidly changed so you can transition from dense to porous within a single fabric. For heart valve fabrics, this means blood leakage can be prevented inside the valve while native tissue ingrowth is encouraged outside. Knits are very compliant, allowing the implant to stretch and move with the body, reducing patient discomfort and restoring natural mobility.

Applications of knitted heart valve fabrics include vascular prosthesis, hemostasis, cardiac support devices, and valve sewing cuffs.

Woven Heart Valve Fabric

Weaving technology is rapidly evolving and can be used to create heart valve fabrics by interlacing combinations of two or more monofilament or multifilament non-absorbable yarns in a perpendicular fashion. The various ways that the yarns are interlaced allows textile engineers to create complex architectures, such as the three-layer architecture of the valve leaflets, while tailoring critical characteristics such as density/porosity and thickness. The completed textile structures can be used to promote growth of cells in the scaffold based on the orientation of the yarn.

Woven fabric configurations include tubular, flat, tapered, or near-net fabrics that are beneficial due to their low porosity (which is important for containment and cardiovascular fluid transfer), dimensional stability and high-tensile strength.

Patient Benefits with Heart Valve Fabrics

Thanks to modern technology advancements, the possibilities for biomedical textiles are practically limitless and are greatly advancing less invasive cardiovascular procedures using lower profile devices. Heart valve fabrics offer superior flexibility, and with highly customizable geometries, provide biocompatible solutions that can support improved patient healing and promote the regeneration of damaged cardiovascular tissue.